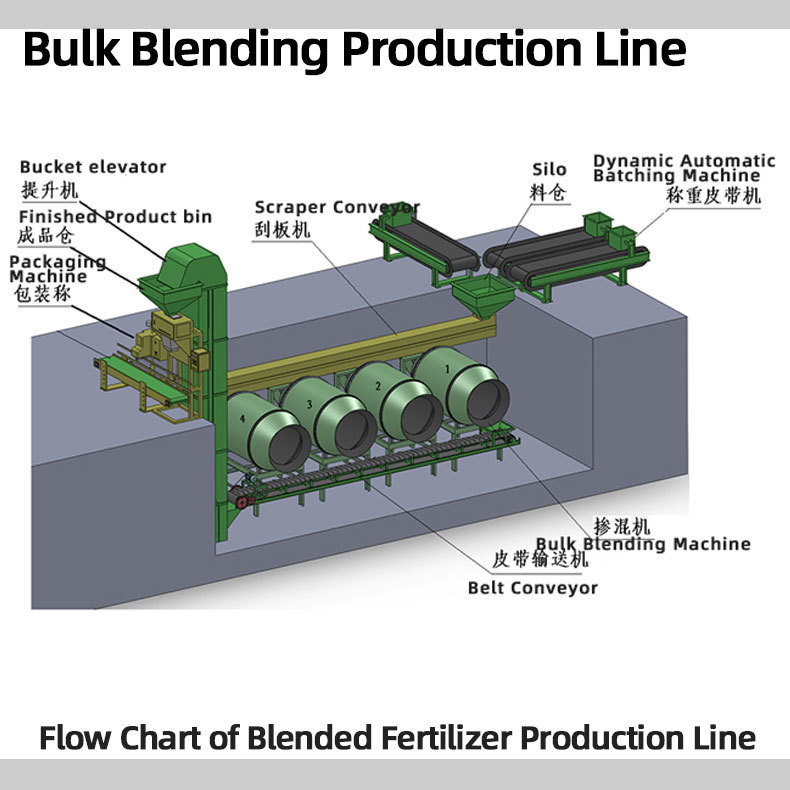

NPK fertilizer bulk blend production line

The bulk blend fertilizer production line, also known as the BB fertilizer production line, is a complete equipment system designed for the production of blended fertilizers. This production line system mainly consists of a silo (for two or more raw materials), a batching system, a mixing system, a control system, and a packaging system.

It is mainly used to process basic fertilizer granules such as urea, diammonium phosphate (DAP), potassium chloride, and organic fertilizers. These granules are fed into the mixing system in specific proportions through the batching system with precise formula control (with an error of ±0.2%). After being mixed by a blended fertilizer mixer, the mixture is then transferred to the packaging system.

Key Notes on Terminology:

- Blended Fertilizer/BB Fertilizer*: "BB" stands for "Bulk Blending", referring to fertilizers made by physically mixing different granular fertilizers in specific ratios to meet crop nutrient needs, without chemical reactions during production.

-Diammonium Phosphate, DAP*: A common high-phosphorus compound fertilizer, typically written as "DAP" in industrial contexts for brevity.

-Error of ±0.2%*: This highlights the high precision of the batching system, a critical technical parameter in fertilizer production to ensure consistent nutrient content of the final product. |

Main Equipment of BB fertilizer blend production line

- Raw Material Storage System: Consists of multiple silos for storing basic fertilizers such as urea, diammonium phosphate, and potassium chloride. Silos are typically constructed of steel and equipped with level indicators and unloading devices, such as screw conveyors or belt conveyors, to provide real-time information on raw material inventory and transport the raw materials to the batching system.

- Batching System: Consists of electronic scales, batching hoppers, and conveying equipment. Based on the production formula, the electronic scales accurately measure the amounts of various raw materials and convey them to the batching hopper for mixing, ensuring accurate batching.

- Mixing System: The main equipment is the mixer, with common examples including twin-shaft paddle mixers and drum mixers. Twin-shaft paddle mixers offer fast mixing speeds and high uniformity, making them suitable for large-scale production. Drum mixers, with their simple structure and easy operation, are suitable for small and medium-scale production.

- Packaging System: Includes packaging machines, conveyors, and bag sewing machines. The mixed fertilizer is conveyed via a conveyor to the packaging machine for quantitative packaging, which is then sealed by a bag sewing machine, achieving automated metering, filling, and sealing. - Control System: Typically, a PLC or DCS system is used to centrally control the entire production process, including raw material transportation, batching, mixing, and packaging. This allows for automated control, parameter adjustment, and fault diagnosis.

( From left to right, they are: process flow diagram, fully automatic batching system, customer site.)

Main Features of the Blended Fertilizer Production Line

① High Level of Automation: Utilizing an advanced control system, the system automatically measures, mixes, packages, and delivers the raw materials, improving production efficiency. - High Flexibility: Raw material types and proportions can be adjusted to meet market demand and crop growth requirements, producing blended fertilizers with different formulations.

② Stable Quality: Precise metering and mixing ensure consistent quality in each batch of fertilizer, meeting crop growth requirements.

③ Small Footprint: The production line is low in height, requiring minimal plant space, making it suitable for small fertilizer plants and fertilizer distributors.

④ Economical and Practical: The capital investment in plant and equipment is minimal, offering a high cost-effectiveness ratio.

Bulk Blend Fertilizer Production Line Process Flow

Step 1: Raw Material Preparation: Store the various raw materials separately in separate warehouses or silos.

Step 2: Metering and Batching: According to the production formula, the various raw materials are weighed proportionally using metering equipment and fed into the mixer.

Step 3: Mixing and Agitation: Thoroughly mix the ingredients in the mixer to ensure even distribution.

Step 4: Finished Product Packaging: The mixed fertilizer is conveyed via a conveyor belt to a packaging machine for automatic packaging.

Step 5: Finished Product Storage and Transportation: The packaged blended fertilizer is transported via a conveyor system to the finished product warehouse for shipment.

Finished product display:

BB fertilizer or blended fertilizer is a fertilizer containing any two or three of the three nutrients nitrogen, phosphorus and potassium. It is made by simple mechanical mixing without significant chemical reactions during the mixing process. The advantage of BB fertilizer is that it can produce various specifications of special fertilizer according to user needs, which is more suitable for soil testing and formula fertilization.

Customer Cases:

Tianci Heavy Industry focuses on technological innovation and product quality, provides customers with one-stop service, is market-oriented, seeks development through innovation, survives by quality, and wins the trust of customers with perfect after-sales service.

Equipment delivery:

Tianci Heavy Industry has more than 20 years of experience in the production of organic fertilizer and compound fertilizer equipment. It has worked closely with many customers at home and abroad and is deeply favored by new and old customers.

About the Company:

Established in 2000, Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. is a prominent manufacturer in China, specializing in the design, production, and supply of high-quality fertilizer machinery. With over 24 years of production experience and 16 years of export expertise, we have built a reputation as a leading brand in the fertilizer machinery industry. Our commitment to innovation and quality has allowed us to become a trusted partner for fertilizer producers around the world.

FAQ:

Q: What are the main equipment for bulk blend fertilizer production line?

A: The equipment for a bulk blend fertilizer production line primarily includes a raw material batching system, a bulk blend fertilizer mixer, a packaging system, a dust removal system, and an electronic control system. Select the equipment and model to customize based on your production needs.

Q: What raw materials can the fertilizer blending equipment process?

A: It can process common raw materials such as granular urea, diammonium phosphate, potassium chloride, potassium sulfate, organic fertilizer granules, etc., and supports the blending of 0.5-6mm particle specifications.

Q: How much power does a fertilizer bulk blend mixer?

A: Small ones are generally around 10kw, and the power consumption increases with the output.

How much does a bulk blend fertilizer production line equipment cost?

Small-scale ones are generally 1-5 tons, and the price of a complete set of bulk blend fertilizer production line equipment is about $7000-$22,000.

Medium-sized ones generally have a capacity of 5-15 tons/hour, and the price of a complete set of bulk blend fertilizer production line equipment is about $25,000-$60,000.

The price of a complete set of equipment for a large-scale bulk blend fertilizer production line is generally more than $60,000.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!