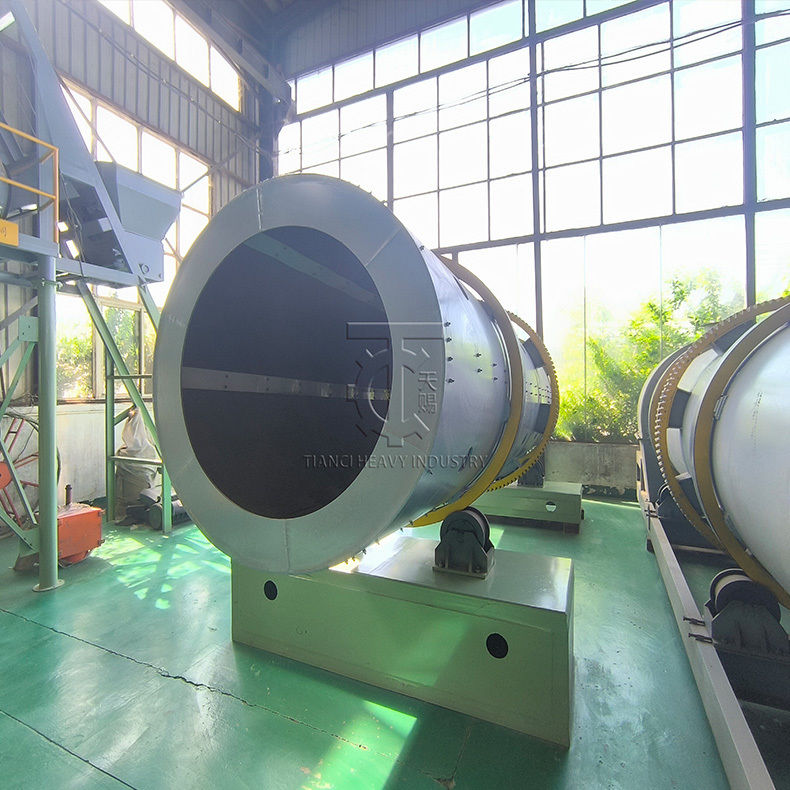

製品紹介

このNPK肥料生産工場は,有機物質の長期的土壌栄養効果を素早く作用する主要な無機栄養素 (窒素)農作物や土壌条件に合わせた 高性能肥料を生産できます純粋に合成的投入物への過剰依存を減らすと同時に持続可能な農業を支援する.

Pアラメーター

|

モデル

|

内側 直径

(m)

|

傾向

(° )

|

ローテーション スピード

( r/min )

|

パワー

( kw)

|

容量

( t/h )

|

|

ZG1240

|

1.2

|

2から5

|

4.7

|

5.5

|

1〜3

|

|

ZG1450

|

1.4

|

2から5

|

5

|

7.5

|

3〜4

|

|

ZG1560

|

1.5

|

2から5

|

5

|

11

|

5 から 8

|

|

ZG1870

|

1.8

|

2から5

|

3.9

|

15

|

8〜10

|

|

ZG2080

|

2

|

2から5

|

3.9

|

18.5

|

10〜15

|

|

ZG2290

|

2.2

|

2から5

|

3.2

|

22

|

15〜20

|

|

ZG24100

|

2.4

|

2から5

|

3

|

30

|

20〜25

|

作業プロセス

1原材料の調製:NPK,有機物質 (肥料,作物残留物など) は発酵 (分解および無菌化) され粉砕されます.不機質物質は粉砕され,混ぜるのに均質な粒子のサイズを確保するために事前処理されます..

2. 自動バッチ&ミックス:このシステムは,目標肥料の配列に従って,準備された有機物質と無機物質を自動的に計測し混合し,均質な混合を保証します.

3粒状:混合した材料は粒子 (回転ドラム,ディスク,またはエクストルーダー) に供給され,望ましいサイズの球状または円筒状の粒子を形成します.

4乾燥:粒子は低温 (約90°C) で乾燥し,熱に敏感な有機成分と有益な微生物を保存し,湿度を10〜15%まで減少します.

5冷却:乾燥した粒子は冷却システムで環境温度に冷却され,構造を安定させ,水分再吸収を防止する.

6スクリーニング:粒子は振動するスクリーンを通り過ぎて,大きすぎる/小さすぎる粒子を分離し (混合段階に再利用され) 均質な大きさの製品を保持します.

7選択用コーティング:均質な粒子は,栄養素の放出制御や凝縮防止性能を高めるために機能的材料で (必要に応じて) 覆う.

8パッケージ:完成した粒子は自動的に重量化され,袋 (25kg,50kg,または散装) に詰め,保管または輸送のために密封されます.

Q&A

Q: その通り あなたの工場は,販売された機器について,販売後サービスを提供していますか.

A: その通り はい.我々の工場から購入されたすべての機器の 販売後サービスカバーを提供します.

Q: その通り 1年でダンボール粒機でどれだけNPK肥料を生産できるのか?

A: その通り TIANCIのドラム粒子は年間1万~60万トンのNPK複合肥を生産することができる.より高い出力の顧客の要求を満たすために,私たちはカスタマイズサービスを提供します.

Q: その通り ドラムグラナレーターの設置サービスが 購入後に提供されているか 確認してください

A: その通り 設備が工場に到着したら 経験豊富なエンジニアを派遣して 設置指導をして 設備の正常な動作を保証します

Q: その通り ドラムグラナレーターの出力範囲を指定してください.

A: その通り 標準的な毎時間の出力は 1 から 25 トンです.私たちは,あなたの特定の生産ニーズに基づいてカスタマイズされたソリューションを調整することができます.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!